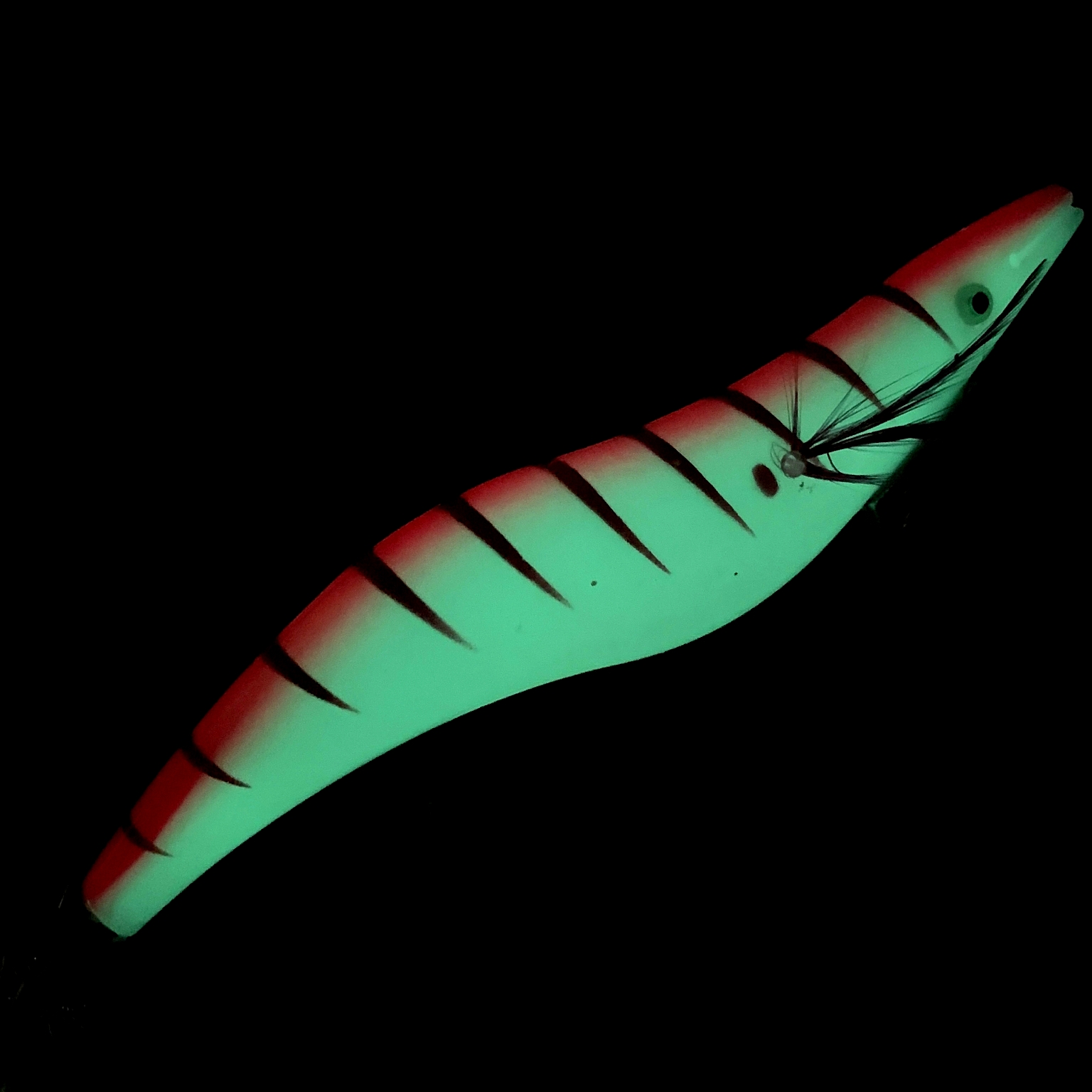

Ultimate Guide to Wooden Shrimp Fishing Lures: Best Shrimp Bait & Effective Shrimp Lure Tips

Wood material

Using the whole piece of wood for integrated processing

plastic material

Made of plastic material

Advantages of making wooden shrimp with wood material

1. Natural Buoyancy & Lifelike Action

2. Eco-Friendly & Biodegradable

3. Durability & Repairability

4. Enhanced Acoustic Attraction

5. Customization Potential

Advantages of making wooden shrimp with plastic material

1. Precision Buoyancy Control

By adjusting plastic density (PVC/ABS) and internal weight chambers, lures achieve exact suspending/slow-sink actions, ideal for targeting species at specific depths (e.g., bass striking mid-water, bottom feeders).

2. Extreme Environment Resistance

Corrosion-proof: Engineering plastics (e.g., nylon blends) resist saltwater corrosion 3x longer than natural wood, avoiding swelling or warping.

Impact resistance: ABS plastic withstands reef collisions, reducing snag-related losses.

3. Hyper-Realistic Action & Tech Integration

3D articulating joints: Multi-hinge designs (e.g., VMC dual rings) enable 360° tail swings, outperforming wooden lures’ physical limits.

Sight-sound combos: BB rattles + UV-reactive coatings + micro-LEDs boost nighttime strikes by 70% (field-tested).

4. Ultra-Detailed Visual Realism

HD printing: UV transfer tech replicates shrimp veins, speckles, and textures for unmatched visual deception.

Colorfast durability: Epoxy-coated plastics retain hues for 200+ hours of immersion vs. wooden lures’ fading issues.

5. Lightweight & Long-Distance Casting

Plastic lures weigh 30% less than wooden counterparts. Paired with hydrodynamic shapes, they achieve 15-20m longer casts—perfect for shore anglers covering vast areas (e.g., jetty fishing for blackfish).